Packaging lines—from blister packers to carton sealers—rely heavily on reliable gear motors. A motor that can withstand variable loads, deliver precise speed, and stay efficient over long shifts is not just a component; it’s a backbone of productivity. Yet, for many packaging equipment enterprises, the decision of which motor manufacturer to engage can feel like a maze of specifications and jargon. This article breaks down the most critical parameters to evaluate, offering a practical checklist that balances performance, cost, and long‑term support.

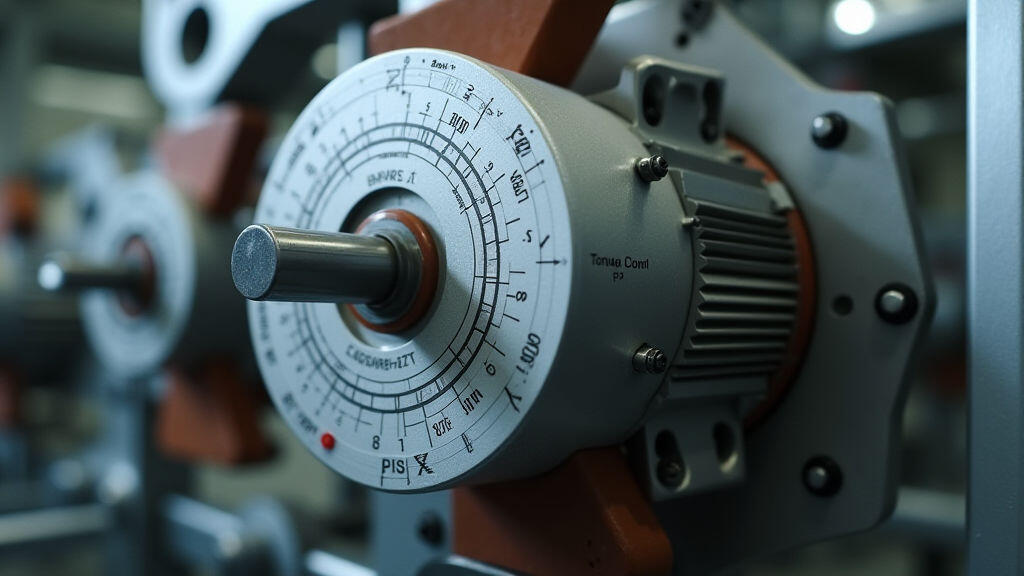

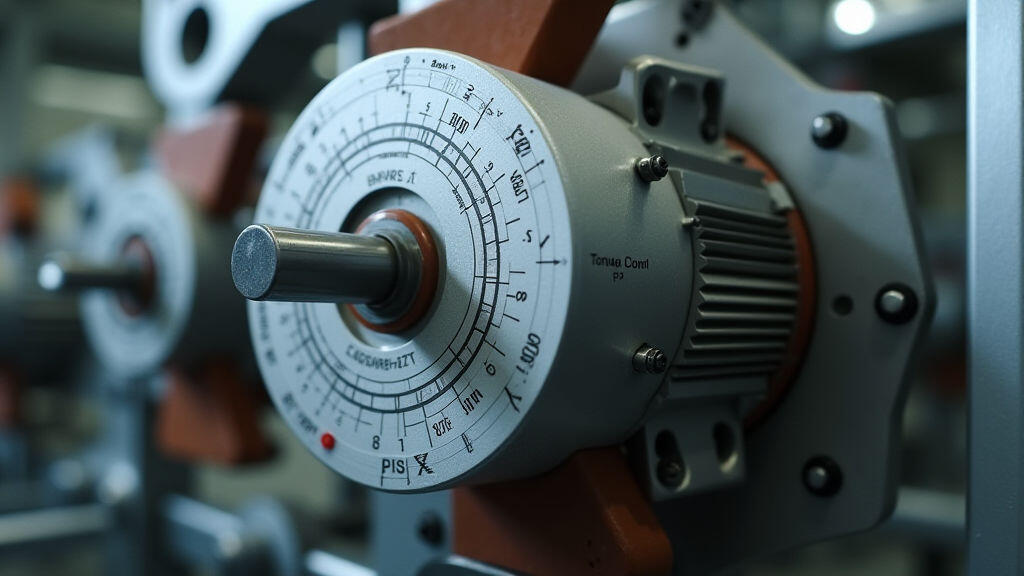

The most obvious metric is torque, but it matters in two forms: static and dynamic torque. Static torque tells you how much force the motor can exert when starting a load; dynamic torque reveals its capacity while the load is moving. Packaging equipment often swings between high‑speed palletizers and slow‑crushing sealers, so a gear motor that can handle both extremes is key.

Speed is equally important. The motor’s nominal speed (usually in revolutions per minute, rpm) should line up with the gearing scheme you plan to use. If you obsess over achieving a perfect 50‑rpm output but the motor can only comfortably run at 45 or 55 rpm, the resulting backlash and vibration can erode the product’s finish.

When a manufacturer offers an adjustable torque curve—via customized gear ratios or an integrated torque sensor—it’s a big plus. It signals that they’re willing to fine‑tune the motor’s performance to match your exact production profile.

Packaging environments can be hot and humid, especially in shelf‑free or high‑volume facilities. A motor that eats up power and over‑heats not only costs more in electricity bills but also shortens its lifespan. Look for motors rated with high efficiency (≥90%) and equipped with active cooling or silicone lubrication. The form factor matters too: a vertically mounted motor can dissipate heat better than a horizontal one in cramped spaces.

Manufacturers that provide a heat‑sink diagram or thermal simulation data demonstrate a hands‑on approach to longevity. Also, verify whether the motor’s torque is continuous or merely short‑duration; continuous torque means the motor can handle sustained loads without overheating, which is vital for long‑running conveyors.

Packaging lines can experience severe mechanical abuse—high impact, constant vibration, and occasional chemical exposure. In this context, durability isn’t a nice-to-have. A motor’s housing should meet IP67 for dust and water protection if your facility deals with brine or compressed air. For food‑grade equipment, look for food‑safe materials like stainless steel or BPA‑free plastics.

Compliance with ISO 9001 or ASME standards signals that the manufacturer follows rigorous quality controls. Seek out proof of testing—such as product lifetime studies—to confirm that the motor can survive the expected cycles per hour of your production line. For instance, a blister packer that cycles 12,000 times per hour demands a motor with proven endurance of at least 200,000 cycles.

Your packaging line is controlled by PLCs, SCADA systems, and sometimes IoT dashboards. The motor’s electrical interface must align with the system’s bandwidth. Many gear motors now feature open‑loop field‑effect transistors (FETs) for fast, precise control. But if you require closed‑loop torque control—especially if the line uses feedback for synchronization—a motor with a built‑in speed encoder or current sensor is essential.

Ease of integration also includes the level of documentation. A comprehensive datasheet, wiring diagrams, and a sample control program reduce installation time. Manufacturers who offer standard IoT modules or support protocols like OPC UA or Modbus TCP future‑proof your motor against digital upgrades.

A motor is a long‑term asset. The manufacturer’s after‑sales support—including warranty terms, spare part availability, and on‑site assistance—can save you thousands of dollars in downtime. Look for:

The ability to upgrade motor firmware or control firmware on the fly is increasingly important as your plant moves towards digital twins and predictive maintenance.

While the initial quotation is critical, the real truth lies in the total cost of ownership (TCO). Cheap motors often juggle inferior torque, slower speeds, or unreliable uptime. High‑quality motors may appear expensive but can yield savings through lower energy consumption, fewer replacements, and less maintenance.

Ask the vendor for a TCO analysis over a 5‑to‑10‑year horizon. It should consider:

A motor that scores high in all other categories but has a prohibitively high TCO may be a poor fit in the long run.

Choosing the right gear motor manufacturer isn’t a one‑off transaction—it’s a strategic partnership that influences your packaging line’s uptime, product quality, and cost structure. By rigorously evaluating torque‑speed match, power efficiency, durability, control integration, after‑sales service, and cost‑of‑ownership, packaging enterprises can secure a motor that stands the test of time and scales with future automation trends.

As packaging industries pivot toward smarter, cleaner, and more adaptable lines—driven by sustainability goals and evolving consumer expectations—having a motor that delivers precise control without compromising reliability will be a competitive advantage. The right gear motor partner today sets the foundation for tomorrow’s innovations, ensuring that packaging equipment remains confident and resilient as market demands accelerate.

Leave A Reply

Your email address will not be published. Required fiels are marked