The modern automated production line is a marvel of engineering, demanding precision, efficiency, and reliability. At the heart of many automated systems lies the gear motor – a crucial component responsible for translating rotational motion into the power needed to drive various mechanisms. Choosing the right gear motor isn't just about picking something that fits; it's about meticulously matching power and speed ratio to the specific demands of the application. This guide draws upon practical experience to offer a comprehensive framework for selecting gear motors for automated production line environments, navigating the complexities and highlighting best practices. With the rise of Industry 4.0 and the increasing emphasis on smart manufacturing, optimizing gear motor performance is more critical than ever.

Before diving into specific types and considerations, it’s essential to understand the fundamental relationship between power and speed ratio.

The gear ratio is the key to tailoring the motor's output to the specific task. A low gear ratio provides high output speed with reduced torque, while a high gear ratio delivers high torque with lower output speed.

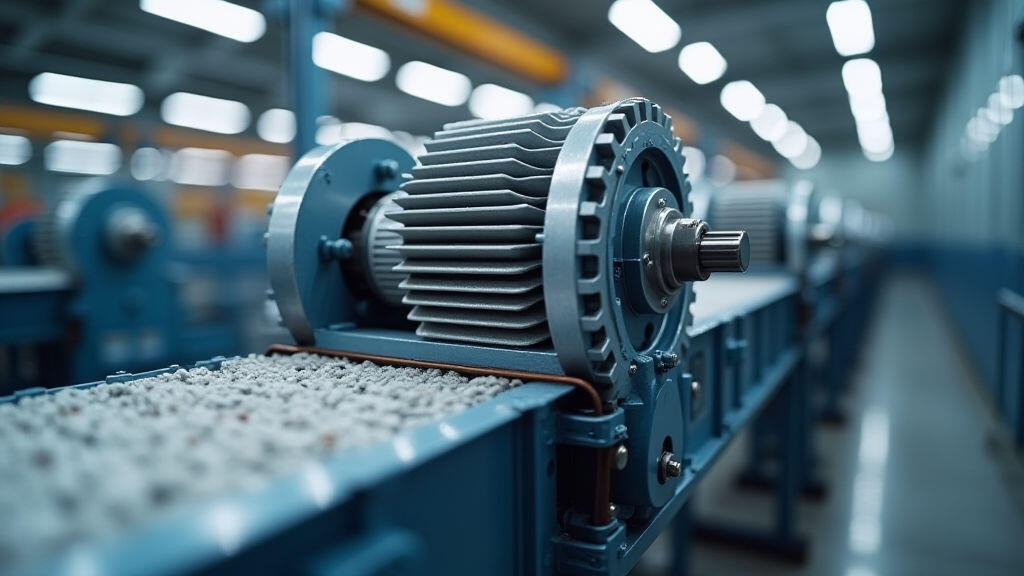

For example, consider a conveyor belt system. You might need a motor with a high speed ratio to drive the belt at a desired speed, even if the motor itself runs at a higher RPM. Conversely, a robotic arm requiring precise, powerful movements would necessitate a high gear ratio to translate a motor's higher speed into the necessary torque.

Selecting a gear motor for automation demands careful consideration of several factors:

Load Requirements: This is paramount. Accurately determine the torque required to perform the intended task. This involves analyzing the inertia of the load, friction, and any potential resistance it might encounter. Consider peak loads and continuous loads separately. Underestimating the load can lead to premature motor failure, while overestimating can result in unnecessary cost and complexity. Tools like mechanical analysis software can significantly aid in load estimations.

Speed Requirements: Determine the required output speed of the driven mechanism. Is a constant speed required, or does it need to vary dynamically? For variable speed applications, consider variable frequency drives (VFDs) – a common component paired with gear motors in modern automation.

Efficiency: Energy efficiency is a crucial aspect, impacting operational costs and environmental footprint. Look for gear motors with high efficiency ratings, particularly in energy-conscious environments. Premium efficiency motors often have higher upfront costs but offer significant long-term savings.

Duty Cycle: How frequently will the motor be operating? Continuous duty applications demand motors designed to handle prolonged operation. Intermittent duty applications have different stress profiles.

Environmental Conditions: Consider the operating environment – temperature, humidity, dust, and potential exposure to chemicals. Choose gear motors with appropriate IP (Ingress Protection) ratings for the environment. For example, in a food processing environment, a higher IP rating is necessary.

Space Constraints: In compact automated systems, minimizing motor size is often essential. Explore different gear motor configurations to find the most space-efficient solution.

Maintenance Requirements: Assess the ease of maintenance. Consider accessibility of components for lubrication, bearing replacement, and other routine tasks.

Several types of gear motors are commonly used in automated production lines, each offering different advantages:

MES-Drive understands the complexities of gear motor selection in automated production. We offer a comprehensive range of gear motors, from standard spur gears to high-precision harmonic drives. Our expert team works closely with clients to analyze their specific needs and recommend the optimal solution. We also provide detailed specifications, performance data, and application support. Our commitment to quality and innovation ensures that our gear motors deliver reliable performance and long-term value.

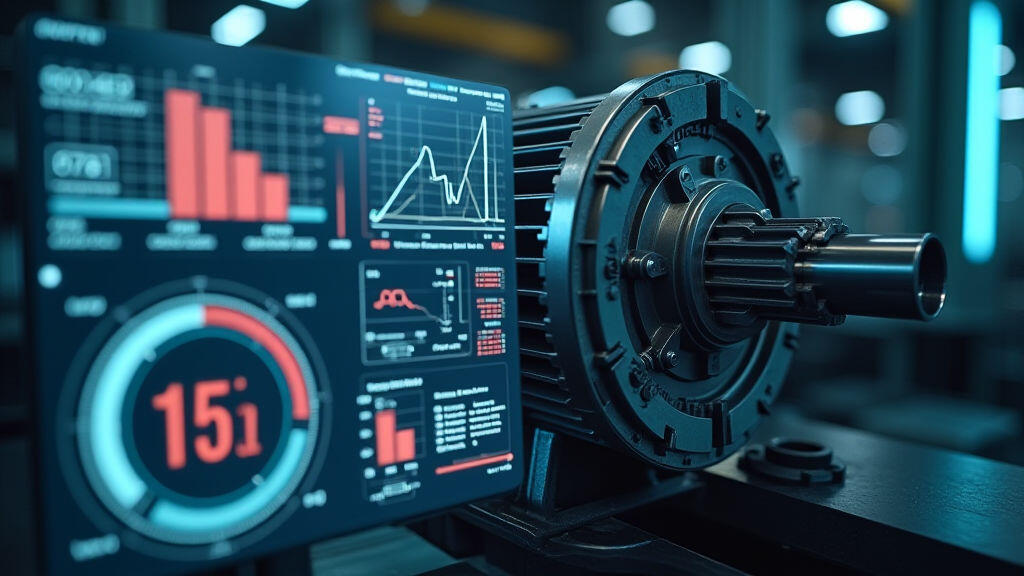

The advent of Industry 4.0 has ushered in an era of data-driven decision making. Integrating sensors and data analytics into automated production lines allows for real-time monitoring of gear motor performance. Metrics like torque, speed, temperature, and vibration can be tracked to identify potential issues early on and optimize motor operation. This predictive maintenance approach reduces downtime and extends motor lifespan. MES-Drive supports this through our IIoT-enabled gear motors, offering remote monitoring and diagnostic capabilities.

Selecting the right gear motor is a pivotal decision in designing efficient and reliable automated production lines. Matching power and speed ratio precisely to application requirements is not just about functionality; it’s about optimizing energy consumption, minimizing downtime, and achieving long-term cost savings. With the increasing sophistication of automated systems and the rise of Industry 4.0, the demand for precise, efficient, and data-driven gear motor solutions is only going to grow. MES-Drive is dedicated to providing the expertise, products, and support necessary to help businesses navigate these complexities and future-proof their automation investments. As companies increasingly embrace smart manufacturing, anticipating future load demands and implementing predictive maintenance strategies facilitated by advanced gear motor technologies will be crucial for maintaining a competitive edge.

Leave A Reply

Your email address will not be published. Required fiels are marked