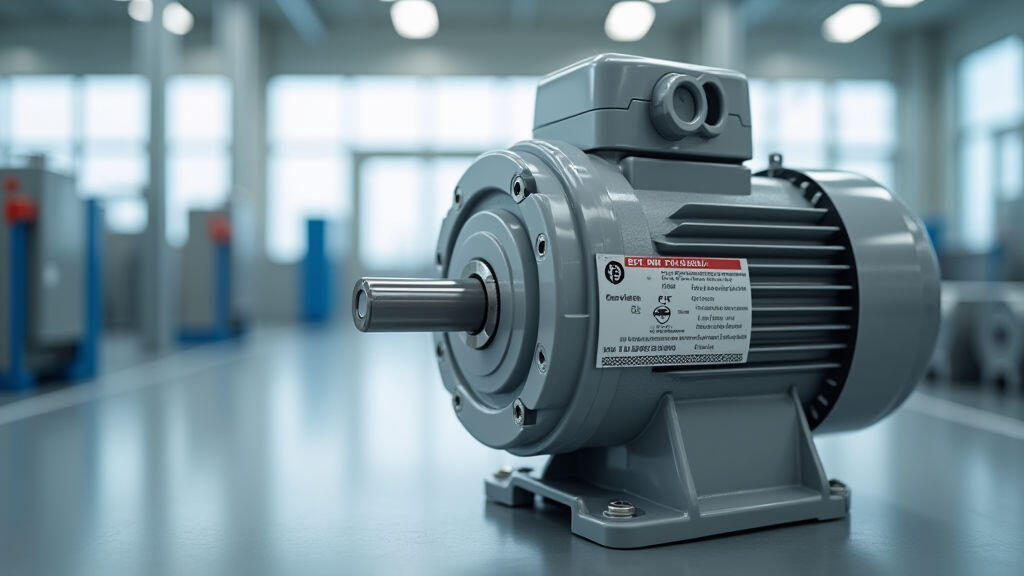

A Practical Guide: Experience Sharing on English Selection of Gear Motors in the Food Processing Field

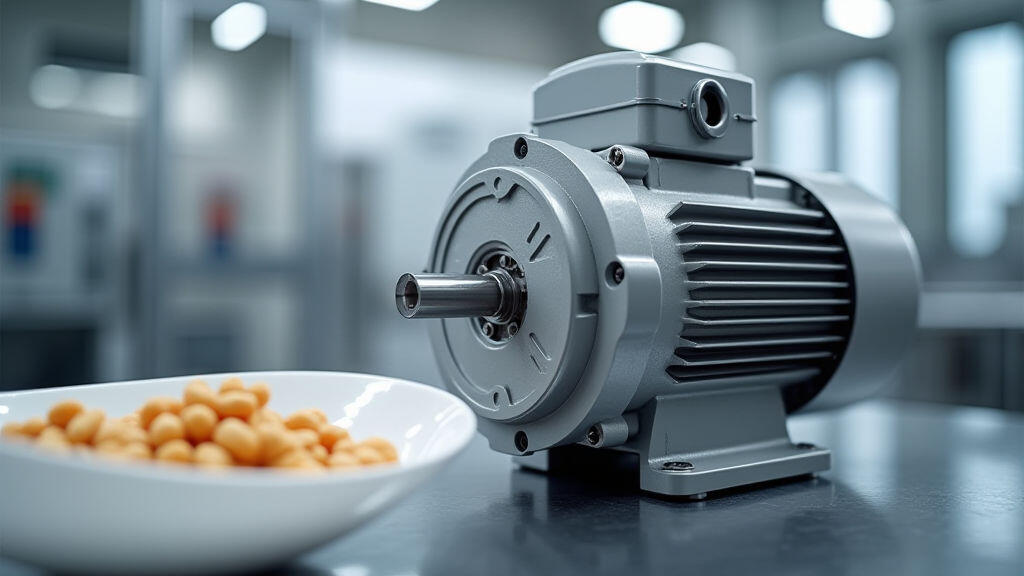

The food processing industry is a demanding environment. Reliability, hygiene, and efficiency are paramount, and the equipment powering these operations must withstand rigorous conditions. Gear motors play a crucial role in automating various processes, from conveyor systems and mixers to packaging and filling machines. Selecting the right gear motor – especially one adhering to English standards for performance and safety – is a critical decision that directly impacts productivity, food quality, and overall operational costs. This article shares practical experience and insights into choosing the optimal gear motor for food processing applications, focusing on English standards, performance considerations, and future trends.

The Importance of Gear Motors in Food Processing

Before delving into selection specifics, let's appreciate the widespread application of gear motors. They offer a unique combination of high torque, precise speed control, and compact size. In food processing, they are employed in:

- Conveyors: Driving belt-driven or chain-driven conveyors for transporting ingredients and finished products.

- Mixers and Agitators: Providing the power for blending and mixing various food components.

- Packaging Machines: Controlling movement in sealing, wrapping, and filling equipment.

- Filling Machines: Ensuring accurate and consistent filling of containers.

- Material Handling: Automating the movement of pallets, boxes, and other materials.

- Grinders and Crushers: Delivering the necessary torque for processing raw materials.

The food industry’s escalating demand for automation, coupled with stricter hygiene regulations (highlighted by the recent focus on food safety recalls and supply chain vulnerabilities), has increased the reliance on robust and efficient gear motor solutions.

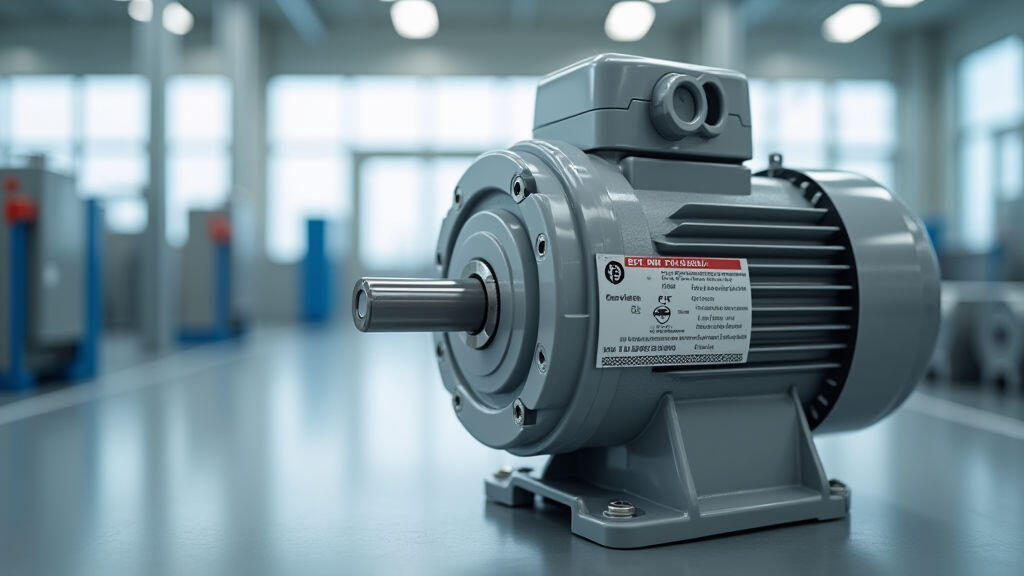

Navigating English Standards and Certifications

Operating within the UK and internationally, food processing equipment must adhere to specific safety and performance standards. Understanding these standards is fundamental to selecting a compatible gear motor. Key English standards to consider include:

- BS EN 60204-1: Machine Safety – Electrical Equipment of Machines: This is arguably the most important standard. It covers the safety of electrical equipment used in machinery, including gear motors. It addresses aspects like enclosure protection, electrical connections, safety distances, and emergency stop functionality.

- BS 5737: Standard for Food Manufacturing Equipment - Hygiene: While not directly focused on motors, this standard influences the selection of motors with appropriate enclosures and materials to mitigate contamination risks. IP ratings (Ingress Protection) are crucial here.

- CE Marking: Certification by the European Union ensures the product meets all relevant EU directives, including those pertaining to safety and electromagnetic compatibility (EMC).

- Food-Grade Materials: For applications involving direct contact with food, the gear motor's materials (e.g., steel, plastics) must be food-grade, complying with standards like FDA (Food and Drug Administration) requirements.

- HACCP (Hazard Analysis and Critical Control Points): While not a standard for motors, HACCP principles influence hygiene and cleanability requirements which impact motor choices.

Selecting a gear motor that meets these standards assures compliance, reduces risks, and contributes to a safer and more reliable operation. Look for manufacturers who provide documentation and certifications illustrating compliance.

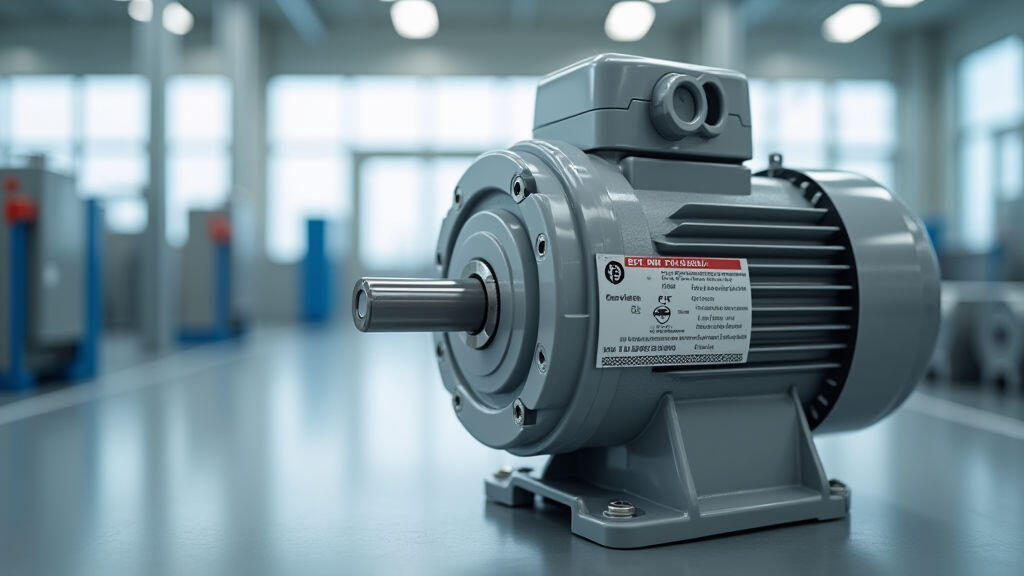

Beyond certification, the gear motor's performance characteristics are critical. Here's a breakdown of key parameters to evaluate:

- Torque: This is the rotational force the motor can generate. Accurate torque calculation is essential to ensure the motor can handle the load without stalling or overheating. Consider both starting torque (needed for initial acceleration) and running torque (required for continuous operation).

- Speed: The rotational speed of the motor (RPM - Revolutions Per Minute) must be precisely aligned with the requirements of the driven equipment. Variable speed gear motors offer flexibility for controlling process parameters.

- Efficiency: Energy efficiency is a key consideration for reducing operational costs. Higher efficiency gear motors consume less power, leading to lower energy bills. IE3 (Improved Efficiency 3) or IE4 (Premium Efficiency) motors are increasingly popular in modern food processing.

- Gear Ratio: The gear ratio determines the relationship between motor speed and output speed. Selecting the appropriate ratio ensures optimal performance for the specific application.

- Duty Cycle: The duty cycle defines the percentage of time the motor can operate continuously. High-duty cycle applications require motors designed for prolonged use. Food processing often requires motors that can handle continuous operation.

- Enclosure Type (IP Rating): The enclosure protects the motor from dust, water, and other contaminants. IP ratings (e.g., IP55, IP65) indicate the level of protection. Higher IP ratings are essential for environments with high levels of dust, moisture, or potential splashes.

- Operating Temperature: Ensure the motor’s temperature range aligns with the factory environment

MES-Drive: A Leading Provider of Food-Grade Gear Motors

MES-Drive is a prominent manufacturer specializing in high-quality gear motors tailored for the food processing industry. They offer a comprehensive range of gear motors that meet stringent English standards, including BS EN 60204-1 and relevant hygiene regulations. MES-Drive's motors are constructed with food-grade materials, ensuring compliance with FDA standards. Their products demonstrate superior efficiency, reliability, and durability. Beyond standard models, MES-Drive excels in providing customized solutions to address specific application challenges. They also provide detailed documentation and support to facilitate seamless integration and compliance.

Future Trends: IIoT and Smart Gear Motors

The food processing industry is undergoing a digital transformation driven by the Industrial Internet of Things (IIoT). The future of gear motors is intertwined with these trends.

- IIoT Integration: Smart gear motors equipped with sensors and connectivity enable real-time monitoring of performance, predictive maintenance, and remote diagnostics. This minimizes downtime and optimizes operational efficiency.

- Energy Optimization: Further advancements in motor technology will lead to even higher energy efficiency, minimizing the environmental impact.

- Customization & Modular Design: Increased emphasis on customized solutions – specifically tailored to unique processing requirements – and modular designs that facilitate easy maintenance and upgrades.

- Advanced Materials: The adoption of new materials (e.g., lightweight composites, advanced coatings) to enhance performance, durability, and hygiene.

Conclusion

Choosing the right gear motor for the food processing industry requires a comprehensive understanding of English standards, performance parameters, and future trends. Prioritizing compliance with BS EN 60204-1, selecting food-grade materials, and considering efficiency are crucial for ensuring safety, reliability, and operational cost-effectiveness. The rise of IIoT and smart motor technology promises further advancements in efficiency, predictive maintenance, and automation. As the food industry continues to evolve, manufacturers like MES-Drive, offering high-quality and compliant solutions, will play a pivotal role in enabling innovation and ensuring the reliable and efficient operation of food processing facilities worldwide. Ultimately, investing in the right gear motor is an investment in the long-term success and sustainability of your food processing operation.

Leave A Reply

Your email address will not be published. Required fiels are marked