The packaging industry is a dynamic landscape, constantly evolving to meet consumer demands for faster, more efficient, and sustainable solutions. At the heart of many packaging processes lies motor technology. Choosing the right motor – whether it's a standard motor or a gear motor – is a critical decision that directly impacts the performance, reliability, and overall cost-effectiveness of packaging equipment. This article shares practical insights, drawing on industry experience, to help decision-makers navigate this choice, especially in today's context of increasing energy costs and the push for Industry 4.0 automation.

The fundamental distinction between gear motors and regular (also known as direct-drive) motors lies in their design and operational characteristics. A regular motor provides rotational force directly to the driven equipment. Gear motors, on the other hand, incorporate a gearbox between the motor and the output shaft. This gearbox serves two primary purposes:

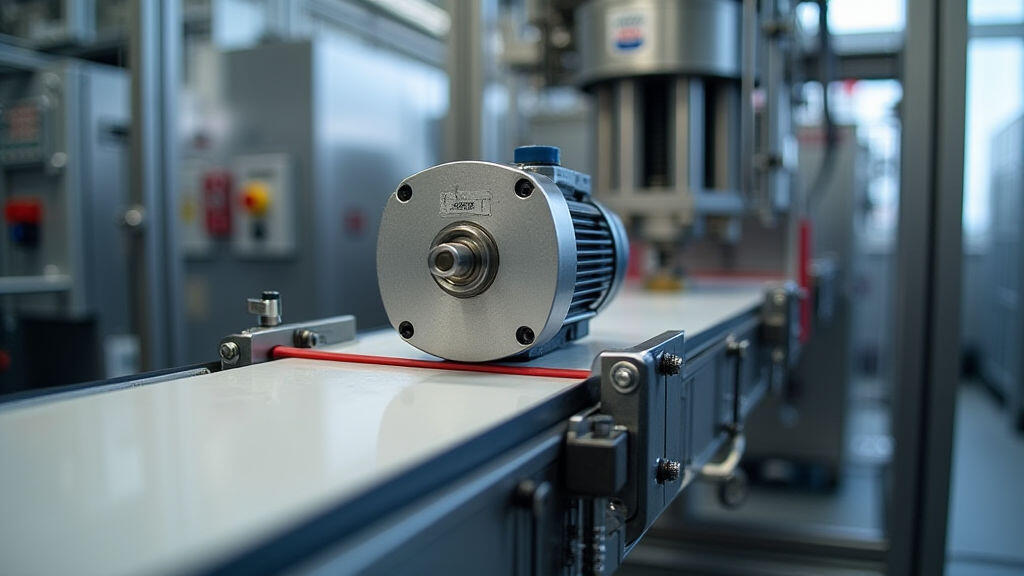

Consider a scenario: a high-speed conveyor system for packaging. A regular motor might be suitable if the load is light, but a gear motor is almost always a better choice to provide the necessary torque to move heavy products and maintain consistent speed, even with varying loads.

Selecting the appropriate motor type requires careful consideration of several factors specific to your packaging application. Here’s a breakdown of the most important aspects:

1. Load Requirements: This is perhaps the most crucial factor. Analyze the weight, inertia, and frictional forces of the load the motor will be driving. High inertia loads (like rotating drums or large rollers) demand higher torque, making gear motors a prevalent choice. Think about machines like:

2. Speed Requirements: Determine the required speed range for the application. Gear motors excel at providing lower speeds with high torque, while regular motors are better suited for high-speed applications where direct drive is feasible. The trend towards faster packaging lines, driven by e-commerce demands and just-in-time manufacturing, is further increasing the demand for controlled gear motor solutions.

3. Accuracy and Positioning: Applications demanding precise positioning, such as automated labeling or intricate product placement, benefit from the controlled speed and torque provided by gear motors. The reduced speed allows for finer control and minimizes overshoot.

4. Energy Efficiency: Traditionally, gear motors had a reputation for lower efficiency due to gearbox losses. However, modern gear motor designs, incorporating advanced materials and optimized gear ratios, are significantly improving energy efficiency. MES-Drive, for example, offers a range of highly efficient gear motors that minimize energy consumption while maximizing performance. It is essential to compare the efficiency ratings of different motor types and models.

5. Maintenance and Reliability: Gearboxes, while adding complexity, also contribute to motor durability by distributing the load and protecting the motor from overload. Regular maintenance, including lubrication and inspection, is vital for ensuring the longevity of gear motors. However, with the advancements in sealed gear designs, maintenance requirements have been reduced substantially.

6. Space Constraints: Gear motors can be more compact than using a separate gearbox with a regular motor, particularly for applications with limited space. This is a significant consideration in modern packaging equipment design.

Let's examine some specific application areas within the packaging field:

The current trend in packaging – smart packaging – is further intensifying the demand for precise motor control. Smart packaging incorporates sensors, RFID tags, and other technologies to track product location, monitor freshness, and enhance supply chain visibility. These features often require intricate and highly controlled motor movements.

Furthermore, the integration of Industry 4.0 principles, including predictive maintenance and remote monitoring, is driving the need for motors with built-in sensors and connectivity capabilities. MES-Drive's smart motor solutions offer real-time performance data, enabling proactive maintenance and optimized operational efficiency. This also facilitates adherence to regulatory requirements and traceability initiatives.

Choosing between gear motors and regular motors isn’t a one-size-fits-all decision. But for a vast majority of applications in the packaging equipment field, especially in the context of increasing automation and the "smart packaging" revolution, gear motors offer superior performance, efficiency, and reliability. As the industry increasingly focuses on energy efficiency, precision, and connectivity, companies like MES-Drive are poised to play a critical role in providing innovative gear motor solutions that meet these evolving demands. Investing in the right motor technology is not just about powering equipment; it's about optimizing entire packaging processes – enhancing productivity, reducing costs, and driving competitive advantage.

Leave A Reply

Your email address will not be published. Required fiels are marked